Maximum flexibility for high-mix, low-volume production

Medium-sized EMS providers are currently under immense pressure: The shortage of skilled workers in the electronics industry continues to intensify, while the demands for efficiency, flexibility, and cost control are increasing. In particular, in high-mix, low-volume manufacturing, where frequent product changes and small batch sizes are the norm, conventional processes quickly reach their limits. This is where our Magic Tower Compact comes in – an intelligent storage and picking system specifically developed to meet the needs of medium-sized electronics manufacturers.

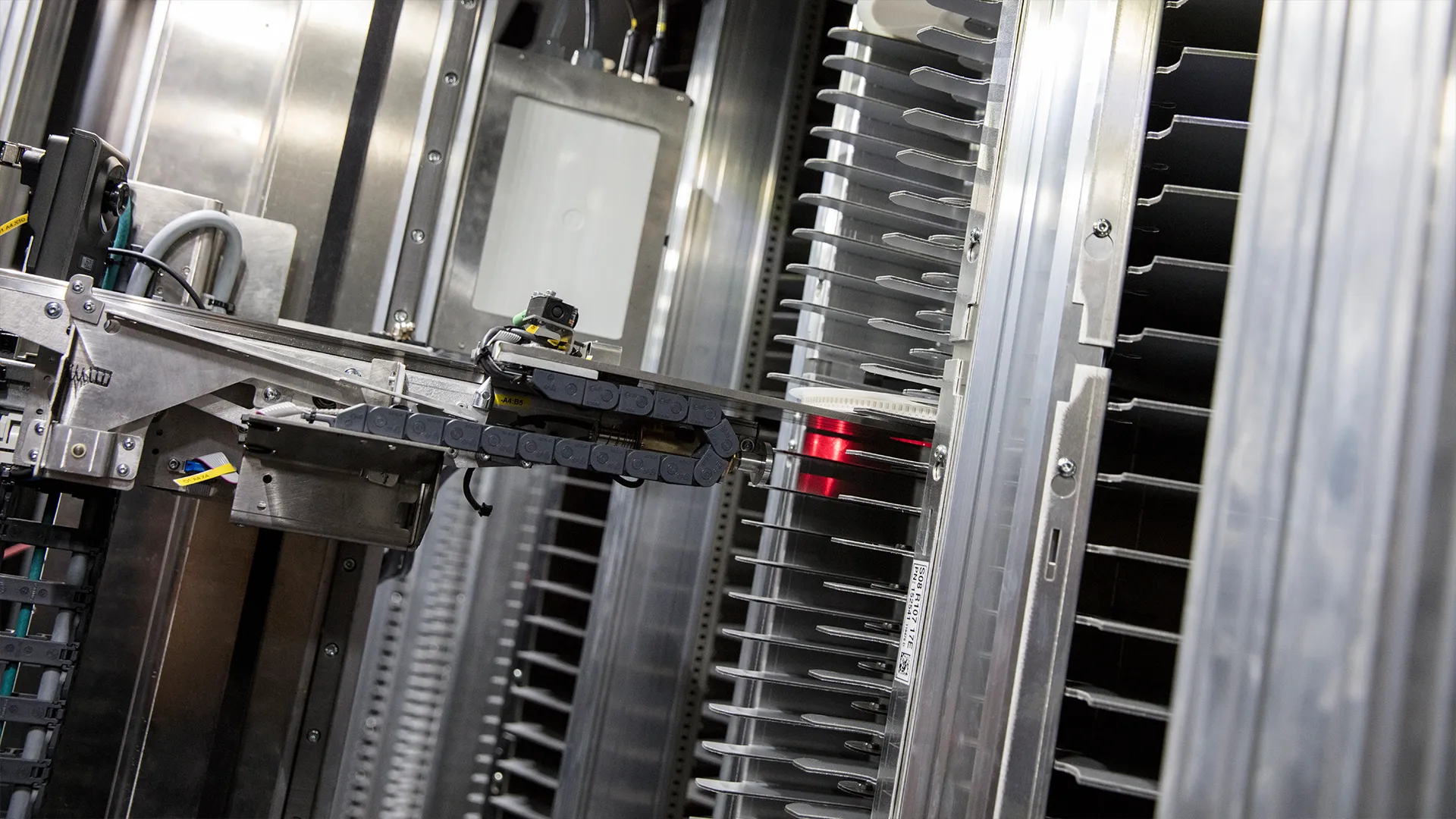

The Magic Tower Compact is a compact, highly flexible storage and picking system that can automatically store and manage different types of packaging. A key highlight is its ability to handle multiple processes in parallel. While the current production line is being supplied with components, the responsible operator can already prepare the next production order and set up feeders for the next job. This significantly reduces downtime and noticeably increases productivity.

Automation for a Flexible and Optimized Electronics Production

Our storage system not only ensures better utilization of the available workforce but also improves process reliability and efficiency. By automating storage processes, manual tasks are reduced, and sources of error are minimized. The system can be seamlessly integrated into existing production environments and scales with the company’s growth.

Our Magic Tower Compact provides a future-oriented solution for medium-sized EMS companies that are under increasing competitive pressure while aiming to modernize their production processes.

Learn more about our Magic Tower Compact and how it can take your production to the next level. Contact us today for a non-binding consultation.