Output Increase through Intelligent Material Logistics

Medium-sized electronics manufacturers have always faced the challenge of maximizing the output of a production line. When it comes to pure output enhancement in component placement, the Magic Tower Compact from Otto Künnecke is the first step, as it prevents downtime on production lines and thereby increases placement performance. As a result, the Magic Tower Compact pays for itself through the increased performance of the entire electronics production. The allocated production budget can thus be utilized optimally.

Overcoming Challenges in Electronics Production through Output Enhancement

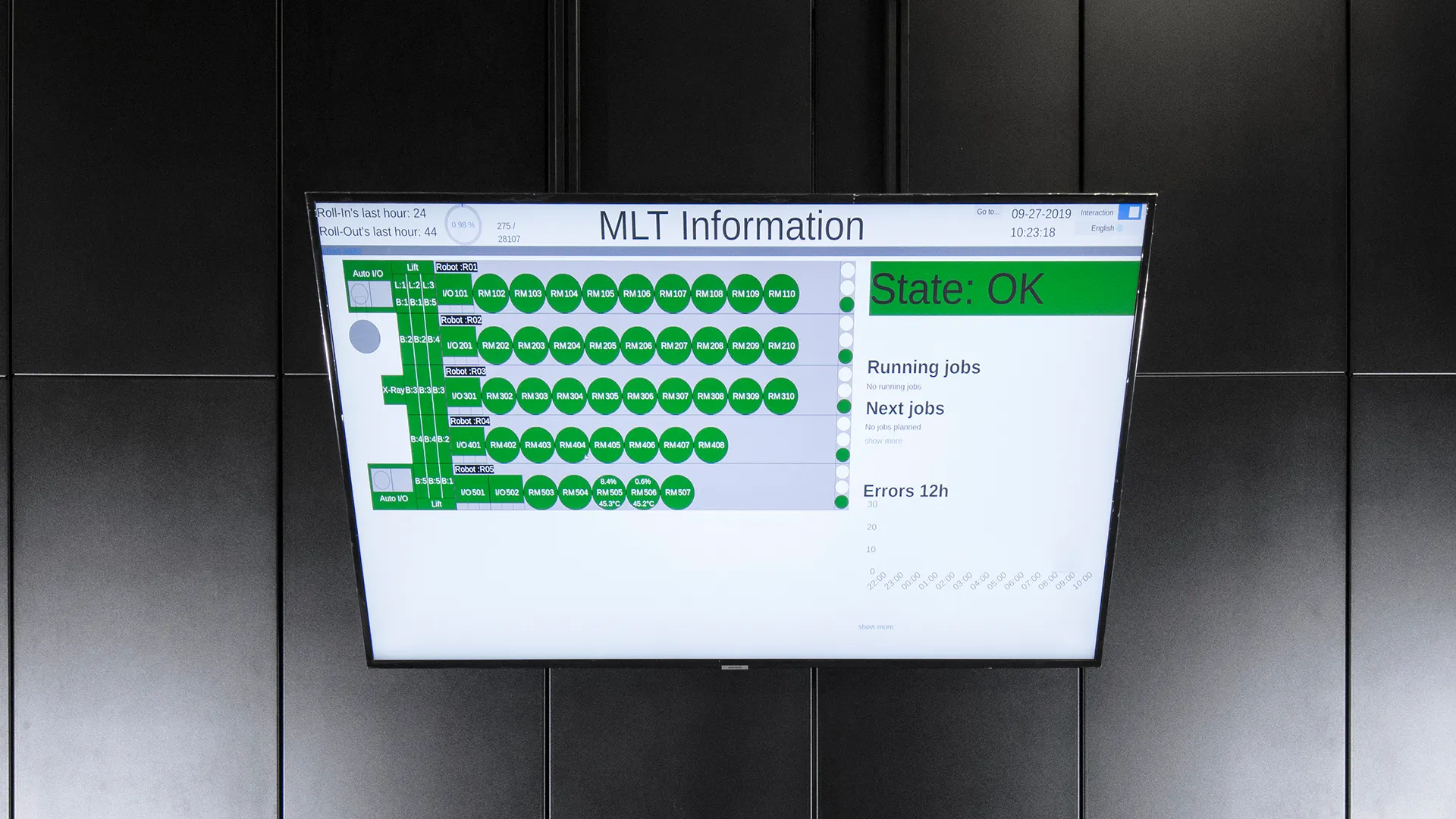

In component placement, time is a cost factor. Long downtimes and setup times due to inefficient material provision lead to performance losses and higher production costs. Our Magic Tower Compact for high-mix, low-volume production addresses this issue. With its automated storage and picking function, it ensures that required components are always available at the right time. This enables continuous operation of production lines, significantly increasing placement performance and reducing costs.

The Magic Tower Compact has been specifically designed for the needs of medium-sized electronics manufacturers and optimizes your budget:

-

Manage cost pressure

Optimized processes reduce production costs and allow for faster return on investment. -

Increase production capacity

Automated material provisioning minimizes downtimes, enabling higher throughput. -

Reduce setup times

Quick and efficient access to components simplifies flexible production and reduces setup times.

Fast ROI through Increased Performance

The use of the Magic Tower Compact not only reduces downtime but also significantly increases productivity. Thanks to the higher production capacity of the existing machinery, the overall investment pays off quickly, providing a decisive advantage for companies under high investment pressure that still need to ensure their competitiveness.