Magic Tower

Fully Automated Storage and Picking System for THT and SMD Components

The Magic Tower by Otto Künnecke

Future-Oriented and Traceable Storage of Electronic Components for Serial Productione

The Magic Tower is a fully automated, flexibly scalable, and modularly designed storage and picking system, tailored to the requirements of modern and future electronics manufacturing. Component reels, JEDEC trays, and other packaging units can be stored and managed fully automatically with complete MSL-compliant traceability.

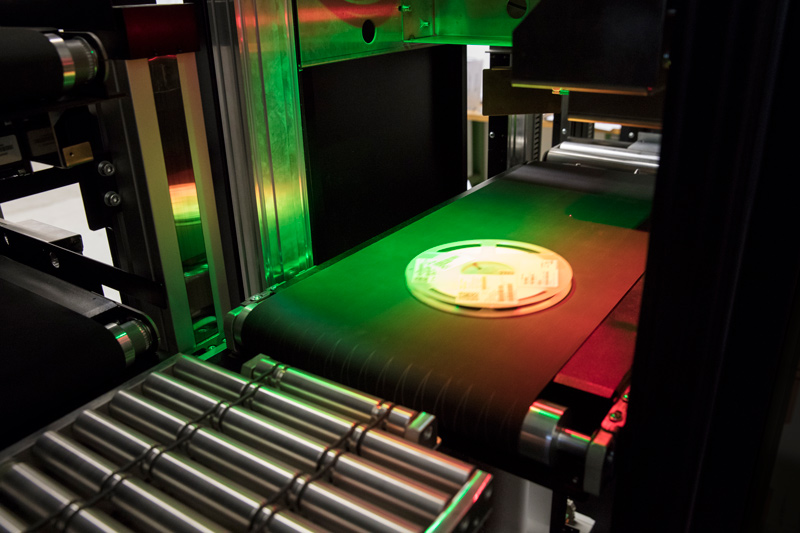

With a capacity of over 100,000 SMD reels, the Magic Tower significantly reduces manual interventions, thus lowering the risk of picking errors while simultaneously saving costs. A key advantage of the system lies in its full adaptability to individual production requirements. For example, with the optional Auto I/O module, up to 60 SMD reels can be automatically stored and retrieved independently of operators.

Intelligent setup based on pick lists enables precise and efficient picking and provision of necessary components. Separate input and output stations guarantee fast and direct access to materials.

Thanks to the consultation provided by Otto Künnecke’s intralogistics experts, the Magic Tower is holistically tailored to your specific requirements. This comprehensive consultation ensures that the system is optimally integrated into your existing processes and meets both current and future needs.

The storage system can be individually configured and supplemented with modules such as MSL drying units, AGV connections, or X-ray component counters. Otto Künnecke’s intralogistics specialists not only view the storage solution in isolation but develop a comprehensive concept together with you, covering all aspects of your internal component logistics. This holistic approach guarantees an efficient and future-proof solution that grows with your company’s requirements. The Magic Tower can be expanded at any time in both size and functionality. Interfaces to ERP and MES systems also ensure seamless integration into your production environment.

Modularity at Its Best

Maximum Flexibility for Individual Requirements – The Magic Tower

The Magic Tower is extremely flexible and can be individually adapted to your needs.

Rotationsturm

Single E/A

Ein- und Auslagerung einzelner Rollen

Auto E/A

Auftragsbezogene Ein- und Auslagerung von bis zu 60 Rollen nach Rüstliste

MSL-Rotationsmodul

Optimale Rücktrocknung und Lagerung gemäß MSL-Level

Bauteilzähler

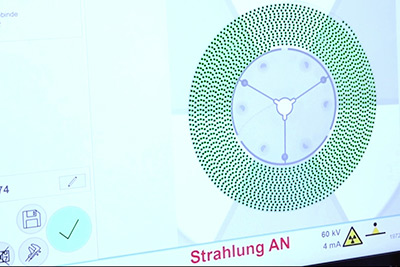

Permanentinventur durch X-Ray-Counter

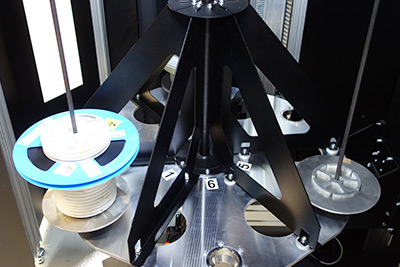

Karussell für Reelholder

Intelligent Setup, Picking, and Provision of All Required Components

Product highlights at a glance:

Boost your productivity and efficiency with the Magic Tower.

- Flexible storage capacity from 1,000 up to 100,000 reels

- Automated goods receipt

- Individual MSL towers for MSL components can be integrated

- Time-optimized output through minimized travel and idle times

- High performance and short picking times thanks to parallel-operating robotic systems

- Storage and retrieval of JEDEC trays

- Consideration of various parameters such as expiry dates, content sizes, physical characteristics, etc.

- Expandable in width and depth, available in different heights: 2.50 m, 3.30 m, 3.80 m

- Proprietary software with interfaces to existing MES and ERP systems

- Low error rate thanks to separate automated input and output processes

- Flexible and coordinated material transport system

- High flexibility and efficient workflow

- Modularly expandable with pick-by-light storage solutions

- X-ray counting systems can be integrated or retrofitted

- Modularly expandable to include storage of THT components

Through communication and solution finding at eye level, we develop optimal storage concepts, enable future-oriented production planning, reduce picking errors, and increase manufacturing efficiency.

Based on many years of experience in the development and production of machine systems and software solutions, we offer customized, innovative storage and logistics concepts worldwide.

At the core of our intelligent warehouse automation concept is the Magic Tower storage and picking system, which, in combination with a variety of additional modules, enables a holistic solution. Starting with goods receipt, through storage, to the provision of relevant assembly and manufacturing parts used in electronics production for EMS and OEM manufacturers.

Since our systems minimize manual interventions and prevent picking errors as well as lost products, they offer real added value for a future-proof production and manufacturing environment.

Ideas create Solutions!

Download Data Sheet

Download our Magic Tower data sheet as a PDF.