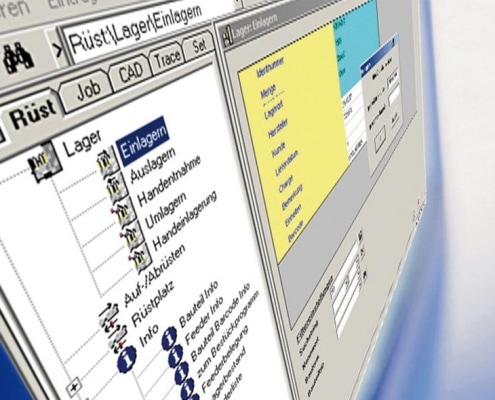

Mex4 Software

Mex4 is the intelligent software solution for managing electronic assembly production, from goods receipt to inventory information and inventory management, including accompanying information.

Modular Software Solution

Efficient Goods and Material Management in Electronics Manufacturing

Modular software architecture for intelligent goods and material management of various assembly and placement systems

Mex4 consists of different software modules.

Each module can be used for a specific function or task within goods and material management.

Interfaces

Connection to External Systems

Connection to External Systems

There are connections to various ERP, PPS, and inventory management systems.

Data transfer (inventory, jobs, etc.) is possible, as well as feedback of component consumption.

In addition, there are interfaces to storage systems, allowing components to be directly called up for setup using Mex4.

- Connecting the software to existing ERP systems via text files, XML-based interfaces, database interfaces, API

- Forwarding machine times and component consumption to higher-level systems